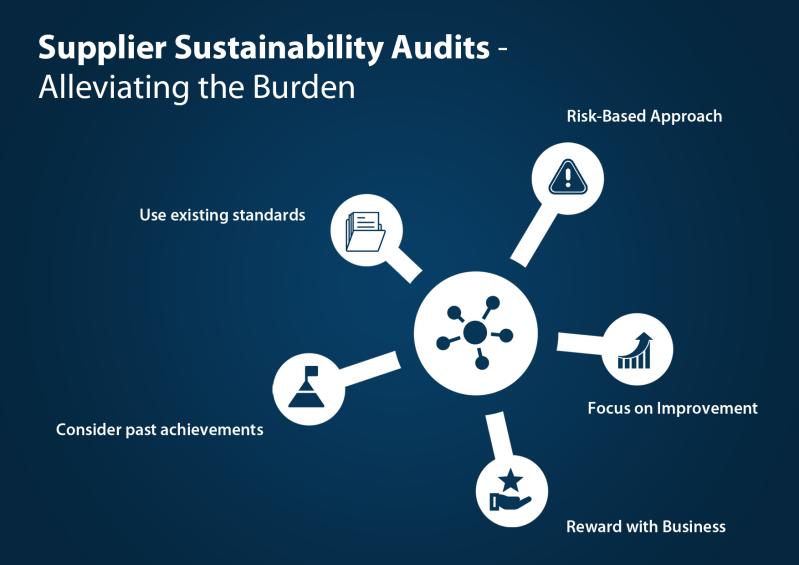

Measure #1: Refer to existing standards

If you compare the codes of conduct of different companies, you will immediately notice that the differences are usually minimal. The differences between common social standards are also small. So there is no need to re-invent the wheel: Most likely, standards and initiatives such as Sedex SMETA, SA 8000 and BSCI already include all the specifications you wanted to include in the code of conduct. Rather than using a custom-developed code of conduct as the basis for supplier audits, our advice is to build on existing standards to help harmonize social standards.

If you want to impose specific requirements on suppliers that are not mentioned in any existing standard, you can add them to your audit protocol.

Measure #2: Take into account what your suppliers have achieved so far

The likelihood that you will be the first or only customer to require a social audit is low. If a supplier already has a valid certificate or audit report from a reliable third party, the question is whether a new audit of the same aspects is really necessary. Benchmark your Code of Conduct against existing supplier standards and review only those aspects that have not yet been adequately assessed.

Action #3: Consider a risk-based approach

Instead of setting audit requirements across the board for the entire supply chain, you can set risk-based priorities. Some vendors provide risk assessment tools that can help you designate audit priorities. These tools typically distinguish:

- Inherent risks for regions and industries (economic situation, wage structure, composition of the workforce, ...)

- Risk factors for individual suppliers, e.g. based on audits and questionnaires evaluated so far.

Measure #4: Focus on improvement

If suppliers are reluctant to undergo a social audit, it may be because they fear possible consequences of a poor audit result. To allay these fears, it can be helpful to offer support and guidance. Avoid a "pass or fail" approach and instead guide suppliers to improve their sustainability performance.

Measure #5: Reward good performance with business

Some companies have had good experiences awarding prizes to suppliers who demonstrate exemplary performance. More important than awards and trophies, however, is the bottom line: When suppliers realize that above-average sustainability performance increases their chances of winning additional business, further incentives are usually unnecessary.

What can DQS do for you?

DQS is your expert partner for social and sustainability audits. With smooth audit planning, experienced auditors and meaningful audit reports, we contribute to the success of your sustainable procurement concept. In addition to conducting social audits, we support you in developing suitable audit concepts, as well as with risk analyses and training.